We maintain an edge in quality and reliability by keeping complete control over the manufacturing process, from components procurement to final inspection. All of our TellerScan, CheXpress and Micro Elite scanners are assembled and 100% tested in the U.S.A. at our plant in California.

We don’t just order parts in bulk from the lowest overseas bidder. Our engineers personally visit our components supply partners on a rotating schedule and conduct regular QA checks on the parts. Every component manufacturer with whom we do business goes through a probationary period of at least six months before becoming a full-fledged supplier.

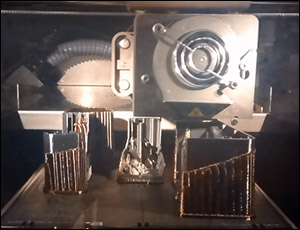

Our in-house team of electrical and mechanical engineers designs every new scanner model from the ground up, so we can fix problems and make improvements without relying on anyone else. 3D-printing prototype components (pictured) lets us test out new ideas in a matter of hours, not weeks or months.

Doing our own product design and manufacturing lets us offer more options and features, and with shorter lead times, than your average hardware maker.

Every device in our TellerScan and CheXpress lines, along with many of our SmartSource scanners, are assembled at our plant in Southern California under strict quality control standards.

How can we afford to build these products in America when most electronics manufacturers simply import theirs from overseas? Because keeping the process under our own roof cuts down on so many problems and defects that it more than makes up for the difference – and keeps our customers happier too.

Every scanner is built at an individual workstation by a single person, not an army of faceless workers each repeating a single task. Having every employee understand every step of the process results in better-made products and more attention to detail. Being able to track each device all the way through the process means more individual accountability, but also the chance to take pride in your own work – both of which have led to noticeably higher quality.

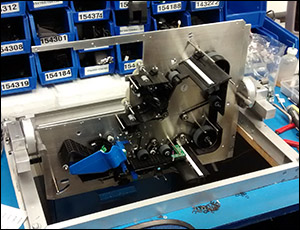

All of our domestically produced scanners go through not one, but two rounds of 100% operational testing by two different groups of inspectors. Every device is hooked up to a computer and physically run through an 85-point live test to make sure it operates perfectly; then put through similar tests in a second QA lab. This meticulous attention to detail has led to an out-of-box failure rate that approaches closer to zero every year.

Any scanners coming back for return or repair go straight to our factory service center, where our own technicians diagnose and fix the problem on-site. Our management (Managers, Directors, and VP levels) and technical teams comprising manufacturing, QA, Engineering, and Service meet weekly to go over any out-of-box failures or serious issues – another reason why Digital Check is #1 in customer service and quality.