When it’s running smoothly, the BranchXpress BX7200 is one of the best high-speed sorting scanners that you can buy. But like any sophisticated piece of equipment, it needs a few adjustments periodically to stay in peak condition. One simple step in particular goes a long way toward keeping your BranchXpress rolling along at top speed.

Those who aren’t familiar with the BranchXpress probably won’t pay much heed to a little gray plastic wheel on the right side of the scanner. But it actually controls one of the most important settings for the long-term proper operation of the device: the discriminator tension.

What is the discriminator, and why is it so important? It’s a little roller that sits at the entrance to the feed track and makes sure that exactly one check at a time is pulled off the stack. It does this by applying just enough pressure against the feed roller (the one that turns and provides the motion that moves the checks) that only one can come off. It’s about the same pressure that you’d feel sliding a playing card off the top of a deck, or sliding a single new dollar bill off the top of a stack.

When the discriminator roller doesn’t do its job, you end up with two or more checks pulled into the track at once. On the bright side, the scanner’s built-in double-feed detection system recognizes this and stops the machine – otherwise, the second check would be covered behind the first when it reached the image sensor, and would appear to simply vanish from your system. Still, you have to stop, pull out the paper from the track, and begin again. Yet this prevents a check from going missing – along with the incorrect balances, unhappy customers, and next-day adjustments that go along with it – but when you’re scanning thousands of checks a day, it’s not something you want to happen often.

Now here’s the “rub,” if you’ll pardon the pun: Each check that feeds into the scanner brushes against the discriminator roller and eventually wears down the roller enough that the pressure is not quite what it needs to be, causing extra checks start slipping into the track, leading to double-feeds. This tends to happen about every 50,000-100,000 items depending on the documents, and there’s no way around it: In order to do its job, the roller MUST press against the paper, and it has to be made of a material with enough give to let a single check through.

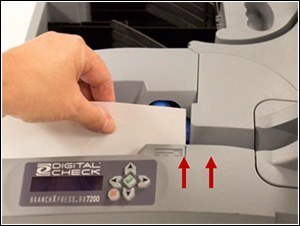

In ordinary scanners, this is not a problem until after many, many months of use. But BranchXpress users tend to scan thousands of items in a day, so they might go through as many checks in a week or two as others do in a whole year. That’s why we gave the BX7200 an adjustment wheel that allows the user to tighten the discriminator roller when it starts to wear down.

|

|

If you’re starting to notice a higher-than-usual number of paper jams and double-feeds, first always blow out the document track with compressed air and clean the scanner rollers with one of our approved cleaning cards and swabs. Too much dirt and dust can cause the rollers to lose their tackiness and have a similar effect to a worn discriminator. A common mistake when noticing double-feeds is to first adjust the tension with dirty rollers and then to clean, which will result in tension being too high with clean rollers. ALWAYS clean the device first before adjusting this setting.

If you’ve cleaned the scanner and still experience double-feeds, then it’s time to adjust the discriminator setting. As with regular screws and knobs, it’s right to tighten, left to loosen. A single click in the clockwise direction is usually enough. Once you’ve gotten the setting right, you should be able to run through two full batches of 250 checks with no more than one misfeed.

As we mentioned above, the discriminator roller typically needs adjusting once every 50,000-100,000 scanned items, which might be once every month or two. The recommended interval between cleanings is once every 8,000-10,000 items, which is closer to weekly. The BX7200 does have an internal counter that keeps track of the total number of items scanned – this can be accessed from within the ScanLite demo program.

Cleaning your scanner properly every 8,000-10,000 documents is important in avoiding double-feeds.

Cleaning your scanner properly every 8,000-10,000 documents is important in avoiding double-feeds.