When dealing specifically with check scanners, there are a few things that it really helps to know. Most importantly, almost all of our scanner models have an “eject” button that you can press to clear any stuck items; pressing this button will run the motors until the paper path is empty.

|

|

It’s important to use the eject button first when you’re clearing a jam, and not try to pull the stuck document out with your hands except as a last resort. There are two reasons for this: First, pressing the button is how the scanner “knows” that the jam has been removed. If you pull the check out manually, the scanner may or may not register that the paper path is clear, and may still treat it as if there is a jam – becoming stuck until you reset it by pressing the button.

Some deposit programs have a “clear jam” or similar button that can be clicked within the software itself. This starts the same process as physically pressing the button on the exterior of the device, and the scanner will register the jam as cleared. This is a supported function in our API – so if your own software doesn’t have this feature, you might consider adding it!

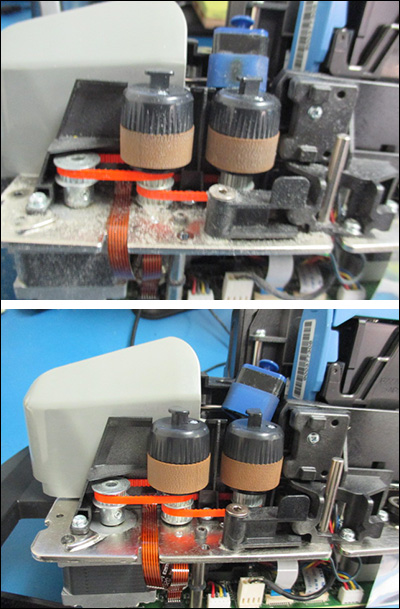

The other main reason why you should not pull out the paper manually is because you might not get all of it – and then your problem can worsen. Any document in the track will, by definition, be pressed between the scanner’s rollers in one or more places, at all times. When you pull the document out vertically, there is a chance that it will tear instead of lifting out of the rollers cleanly. In the best case, you ruin that document. In the worst case, a piece of paper stays behind and gets stuck in the rollers, in the wall of the scanner, or even under the baseplate. The pictures at top right are all examples of this – in each case, the customer reported constant paper jams, which turned out to be caused by an unseen scrap of paper blocking the path. Always eject the paper by running the motors, if possible.

If you do need to clear the jam manually, always try to do so by pulling it forward through the track, not lifting it upward. This will reduce the chance of tearing the item and causing further issues.

One important exception to this rule is the TellerScan TS240, one of our few models that does NOT have an external “clear jam” button. If you experience a jam on the TS240, first use your software’s eject feature, if available – if not, then you can either try using our free ScanLite utility program (which can be downloaded at https://www.digitalcheck.com/drivers/) to run the motors in cleaning mode, which should clear the paper out. Only as a last resort, remove the cover and pull the check out manually.

|

|

Another thing that’s important to understand is that paper jams in check scanners don’t happen without a reason. A check scanner uses feed motors that are much more powerful and more precise than those on your typical off-the-shelf printer or scanner – this is a necessary requirement to make the magnetic MICR ink read correctly. So, you will very rarely get a paper jam “just because.” Every jam has a reason – and most are worth looking into, to make sure another problem is not the underlying cause. In order of highest to lowest frequency, the most common causes of paper jams (or other problems that look like jams) are:

- Torn, crumpled, odd-sized, sticky, or misaligned documents in the feeder tray;

- Misfeeds caused by excessively dirty feed rollers, which lose their grip on the paper;

- Image-quality errors that are not paper jams, but which stop the scanning process because of an unreadable image (often caused by a dirty image sensor)

- “Deep staging,” e.g., shoving a stack of checks too far forward into the feeder – most common on older models

- Double-feeds (two documents at once), most frequently caused by dirty feed rollers, or by a worn discriminator roller;

- Foreign objects in the paper path, including staples, paper clips, dust and debris, or scraps of paper.

As you can see, the root causes of many – if not most – misfeeds have to do with the scanner simply being too dirty. Some of them actually aren’t even misfeeds at all, just other errors that fake you out by bringing the scan cycle to a halt. This is one more reason why regular cleaning is both the simplest and the most important step you can take to keep your scanner running smoothly.

In any check scanner, 90 percent or more of the dirt and rub-off accumulates on the rollers at the very start of the paper path, making that area among the most vulnerable to improper maintenance. The before-and-after photos of this scanner that arrived at our service department for repairs illustrate just how much of a difference this can make. If you do nothing else when maintaining your scanner, just making sure the front feed rollers get clean is the best thing you can do to avoid misfeeds and other issues that will stop the scanner from running. If your scanner seems to start and stop or jam constantly, you can bet that “Have I cleaned it recently?” is the first question you should ask!